Pioneers Of Manufacturing Industrial Equipment

We manufacture all types of instrumentation valves with simple designs for all industries, so making us one of the leading instrumentation valve manufacturers.

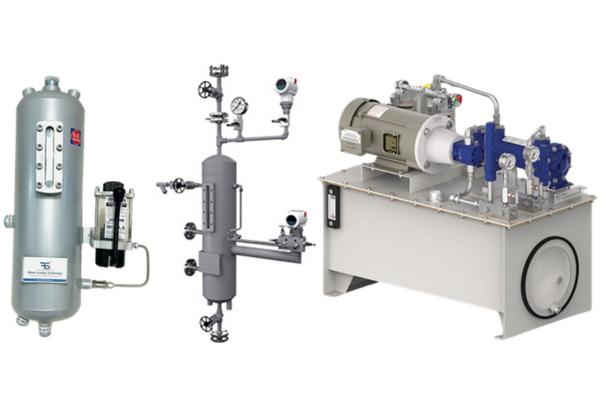

Best quality Seal Support System

We guarantee that our comprehensive range of seal support system are capable of quality and high-performance work.

Cost-effective range of Manufacturing Industrial Equipment

We offer the most cost-effective range of industrial equipment in today’s competitive environment, which we deliver on time in India and across the world.